In the bottling and industrial handling sector, efficiency and delicate container treatment are fundamental factors. When handling lightweight, shaped, or unstable bottles, traditional accumulation systems often show their limits: noise caused by containers colliding, scuffing, pressure, and even crushing.

Europool has found the solution to these issues with Twin Buffer, an innovative accumulation system that combines smooth operation, container protection, and high performance.

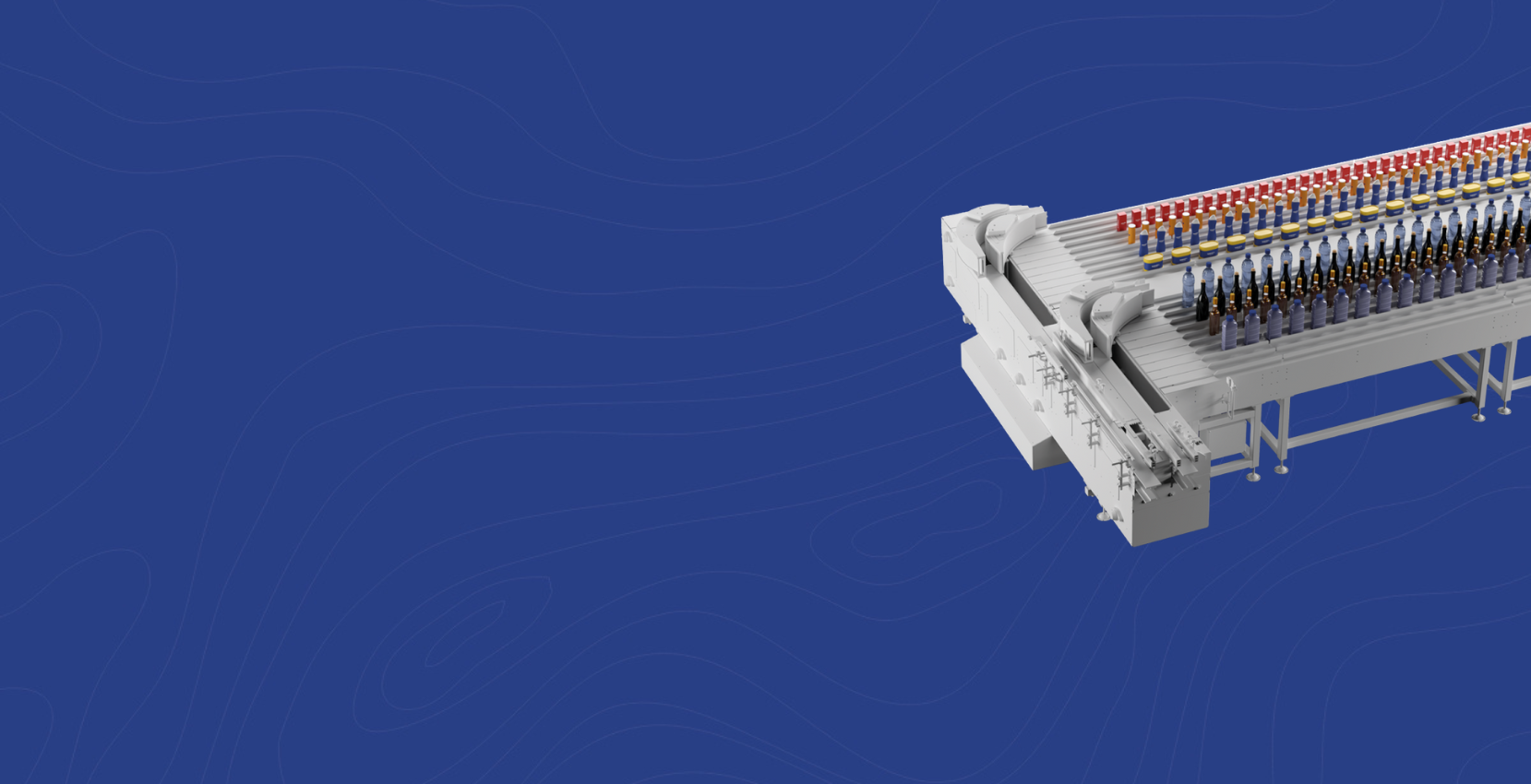

Twin Buffer is a patented accumulation system that allows containers to be moved without ever coming into contact with each other. This feature makes it particularly suitable for shaped, conical, or very lightweight containers (such as empty PET bottles), where the risk of damage and instability is higher.

Thanks to its unique design, Twin Buffer completely eliminates internal pressure between containers, drastically reduces noise, and ensures a gentle and safe treatment, even under the most demanding working conditions.

At the heart of the system is a multi-channel structure, alternately fed and emptied by mobile trolleys and a divider system.

If a downstream stop occurs, the channels simply remain filled without discharging. When production restarts, the system switches to over-speed mode, gradually emptying the channels until returning to optimal operating conditions. All of this happens without pressure, without container contact, and in complete silence.

Twin Buffer represents a qualitative leap compared to traditional accumulation systems.

Companies that adopt it achieve not only higher production efficiency but also the guarantee of preserving the integrity of the most delicate containers, minimizing waste, noise, and line issues.

In a market increasingly focused on sustainability and the use of lightweight materials, this technology becomes the ideal choice for those looking for a reliable, flexible, and future-proof solution.

Twin Buffer is not just an accumulator: it is a strategic ally for modern production, capable of combining innovation, performance, and product care.